Pickling Procedure For Carbon Steel Pipe

Pickle in a solution of 3 1 2 gal of water per lb of citric acid required anhydrous granular citric acid.

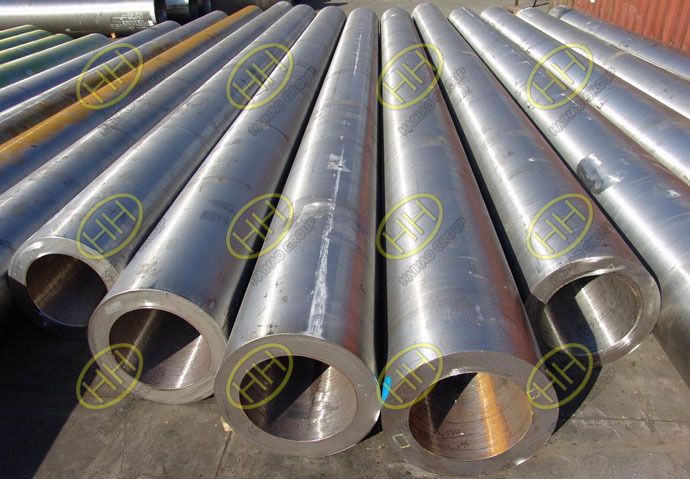

Pickling procedure for carbon steel pipe. Pickling technics for carbon steel pipe carbon steel pipe pickling method currently are used in the construction and management of two trough pickling pickling inner loop. Environmentally safe our pickled carbon steel pipe or stainless steel comes directly from the mill. Part of the carbon steel pickling process is to coat the steel in a light oil after stripping it bare. From carbon steel vessels to carbon steel piping delstar can provide pickling services to fit your needs.

Heat and maintain pickling solution between 82 and 88 c 180 and 190 f. This has to be done immediately or it will start to rust. Procedures for pickling and passivation of carbon steel pipe. Pickling and oiling process.

Pickling pickling refers to the immersion of steel in an acid tank in order to remove the iron oxides or scale from the steel s surface and thus permit the galvanized coating to form upon immersion of the steel in a molten zinc bath american galvanizers association 2015. The installed piping removed after decomposition into pickling bath soak treatment after passing their secondary installation. A surface treatment internal of carbon steel pickling generally consists of the removal of protective coatings and grease in a hot alkaline solution the removal of oxides with inhibited acids and a passivation by means of phosphating or chemical passivation. Fundamentals of geoenvironmental engineering 2018.

Passivation is removing the free iron and other exogenous materials from the surface so that a good passive layer can be formed. A discussion started in 2002 but continuing through 2019. No foreign materials including bits of rust or steel flakes can be present as they would not be filtered through a hydraulic pump for example. Particularly interested in procedures which may be used at job site.

Pickling is the removal of a thin layer of metal from the surface of the stainless steel. You cannot passivate carbon steel. A typical carbon steel pickling job will consist of pre cleaning pickling and oiling. Our out of tank processes allow us to clean and pickle any part that can be transported to our facility.

How to apply video of pickling and passivation chemical on stainless steel for clean and shining look. Pickling is a metal surface treatment used to remove impurities such as stains inorganic contaminants rust or scale from ferrous metals copper precious metals and aluminum alloys. Procedure for pickle citric acid method for carbon steel. Pickling is very prevalent in the steel used for hydraulics.

Please outline procedures for pickling passivation and neutralization of carbon steel pipes for hydraulic systems. It is commonly used to descale or clean steel in various steelmaking processes. Mixtures of nitric and hydrofluoric acids are usually used for pickling stainless steels.