Plasma Nitriding Martensitic Stainless Steel

N was observed 2.

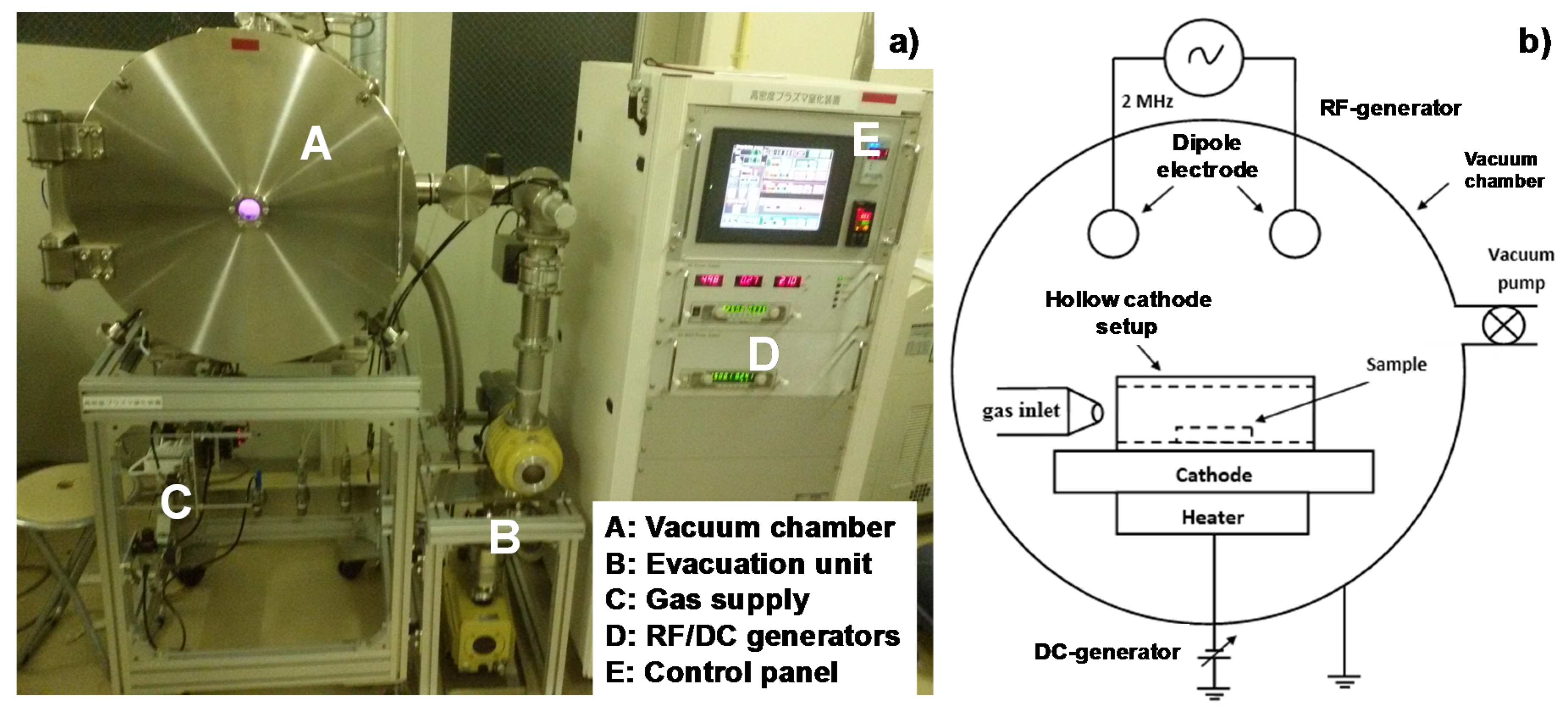

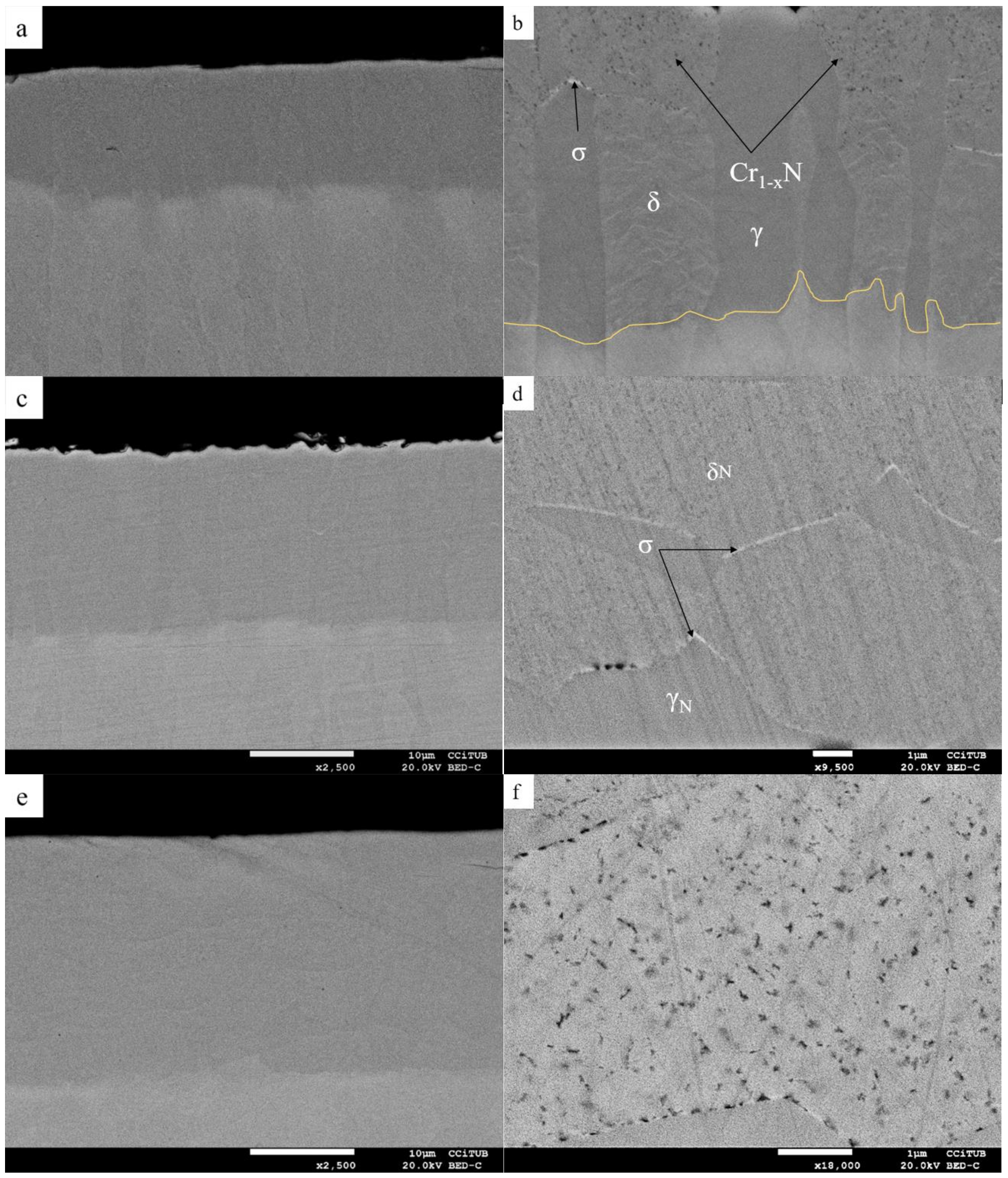

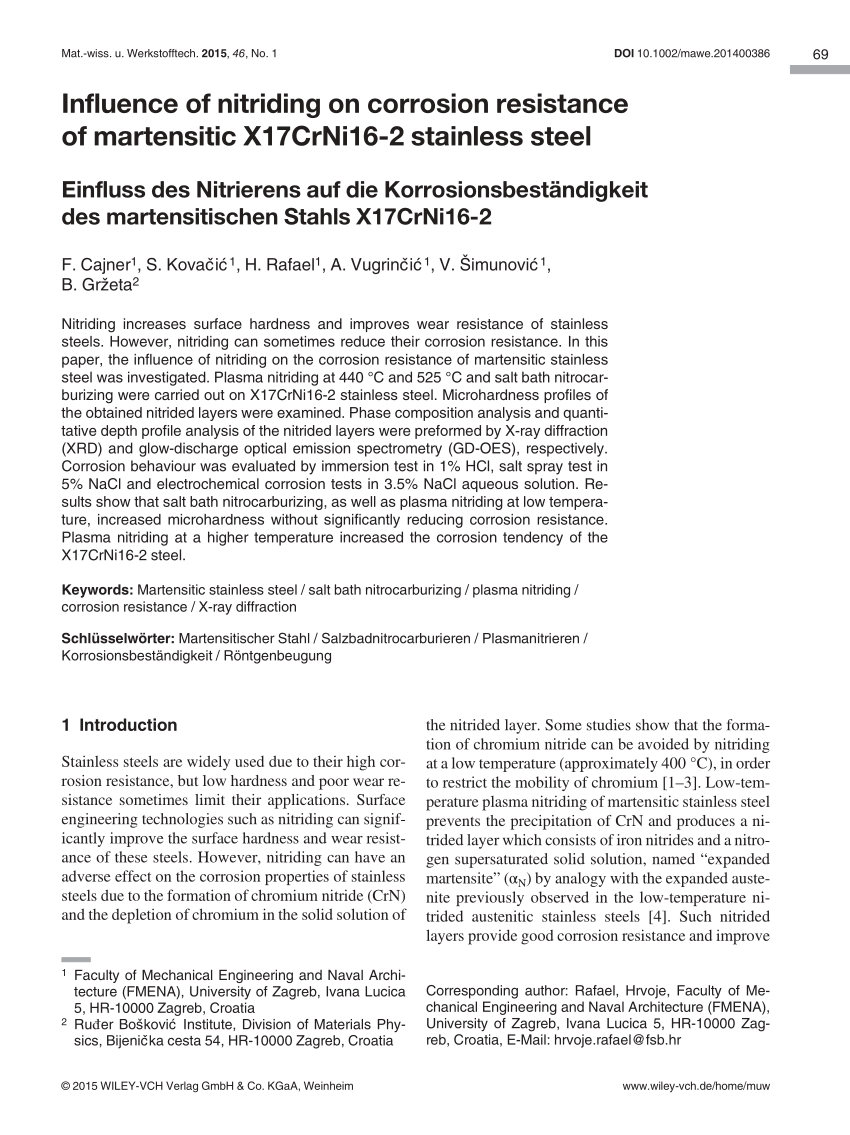

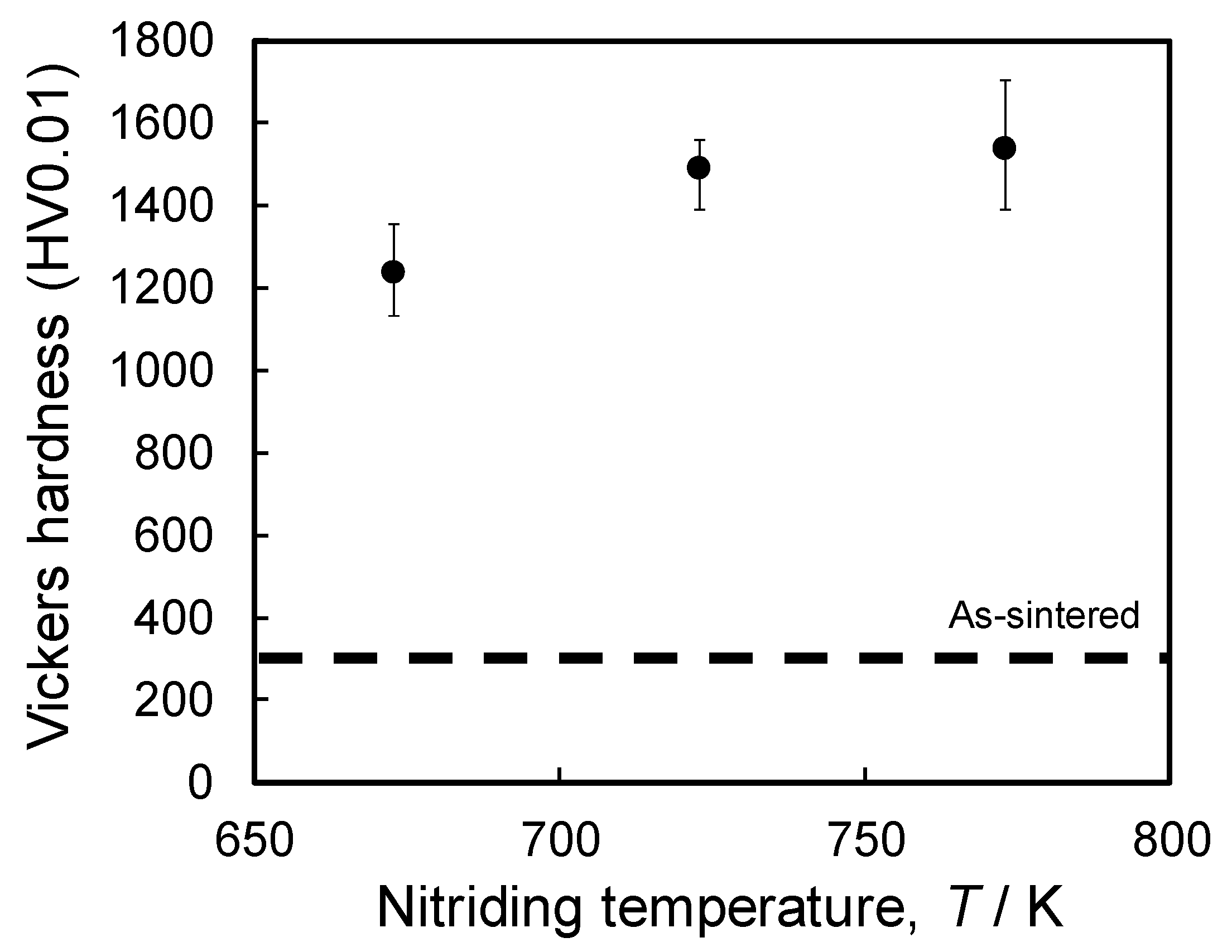

Plasma nitriding martensitic stainless steel. The modified surface was evaluated for micro hardness as well as characterization tests such as optical microscopy sem and xrd. Aisi 304 and aisi 316 is around 450 c depending on process conditions. For temperatures higher than 420 c also cr. Tion nitriding of the alloys is best performed at 2012 f 1100 c and 150 torr.

High temperature gas nitriding of stainless steels is a unique case hardening process for cavitation wear and pitting resistance. Martensitic ferritic and austenitic ferritic stainless steels can all be treated by plasma nitriding to obtain a layer similar to those produced with austenitic stainless steels which is composed of an s phase that increases hardness and wear resistance. During treatment nitrogen diffuses into the steel surface increasing its hardness and wear resistance. The results of nitriding experiments for some martensitic stainless steels show that plasma nitriding can produce a certain thickness of nitriding layer on the surface of stainless steel plates and there is no need to remove the oxide film pretreatment.

Abstract plasma nitriding of 17 4ph martensitic precipitation hardening stainless steels was carried out at 3500c 3800c 4000c 4300c 4500c and 5000c for 4 hours using a mixture ratio of n2 h2 1 4. Low temperature plasma assisted nitriding is a very promising technique to improve surface mechanical properties of stainless steels keeping unaltered or even improving their surface corrosion. Plasma nitriding of the aged a286 resulted in formation of expanded austenite. Solution nitriding of martensitic stainless steels is an efficient and economical surface hardening process when high pressure gas quenched in situ in a vacuum furnace.

High temperature gas nitriding is carried out on stainless steel alloys at temperatures between 1050 and 1200 c 1925f 2200 f. Low temperature plasma nitriding ltpn has proved to be a successful option to increase surface hardness and wear resistance without impairing the corrosion resistance of austenitic martensitic. Low temperature plasma assisted nitriding is a very promising technique to improve surface mechanical properties of stainless steels keeping unaltered or even improving their surface corrosion resistance.