Plasma Nitriding Of Stainless Steels At Low Temperatures

Therefore the chrome can react on the surface after the nitriding with the ambient oxygen forming a chromium oxide layer passive layer to protect against corrosion exactly the same as a non nitrided stainless steel.

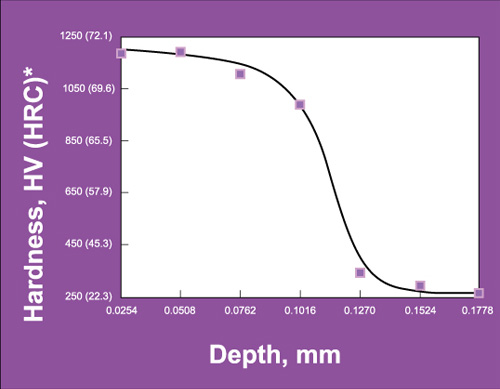

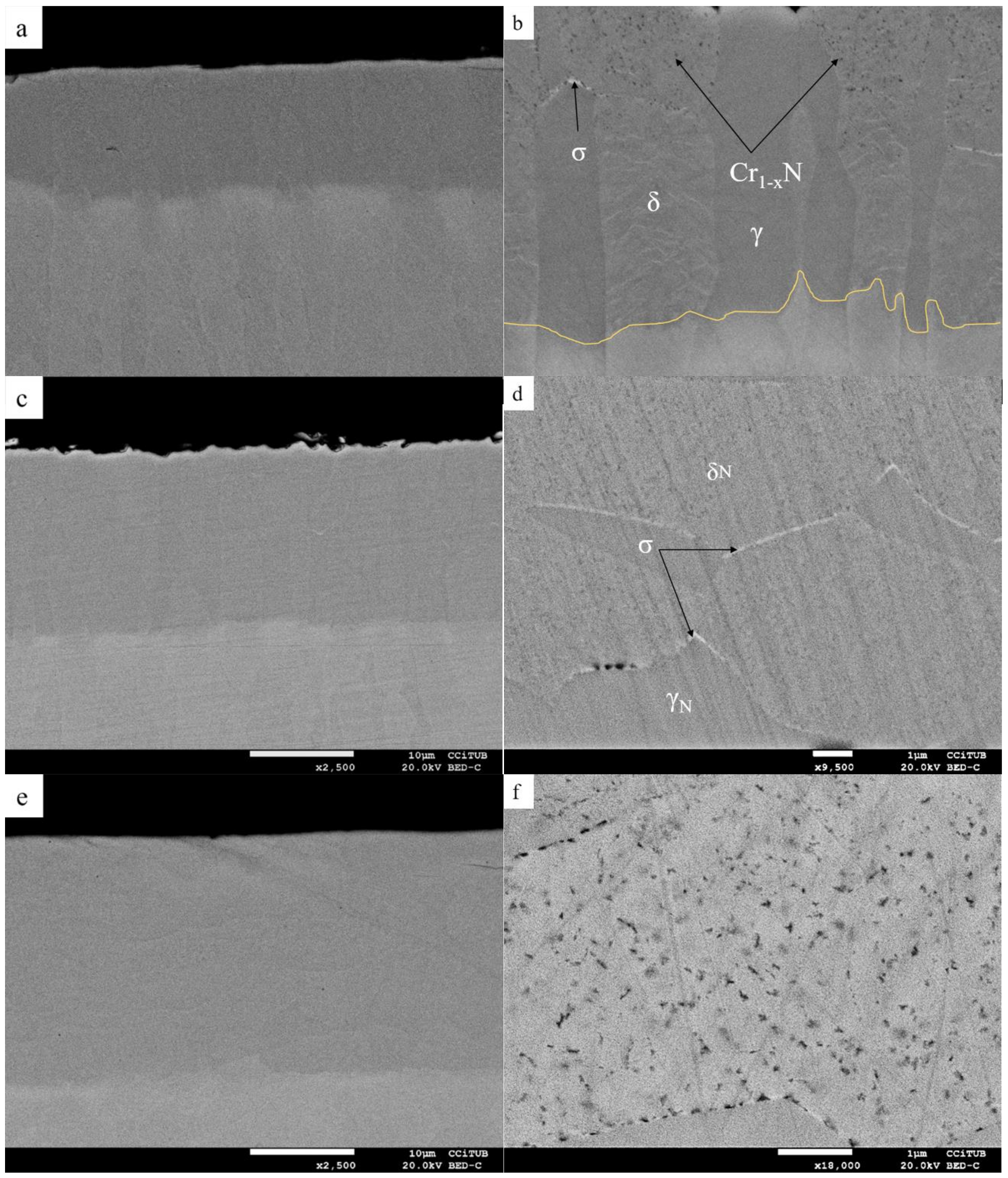

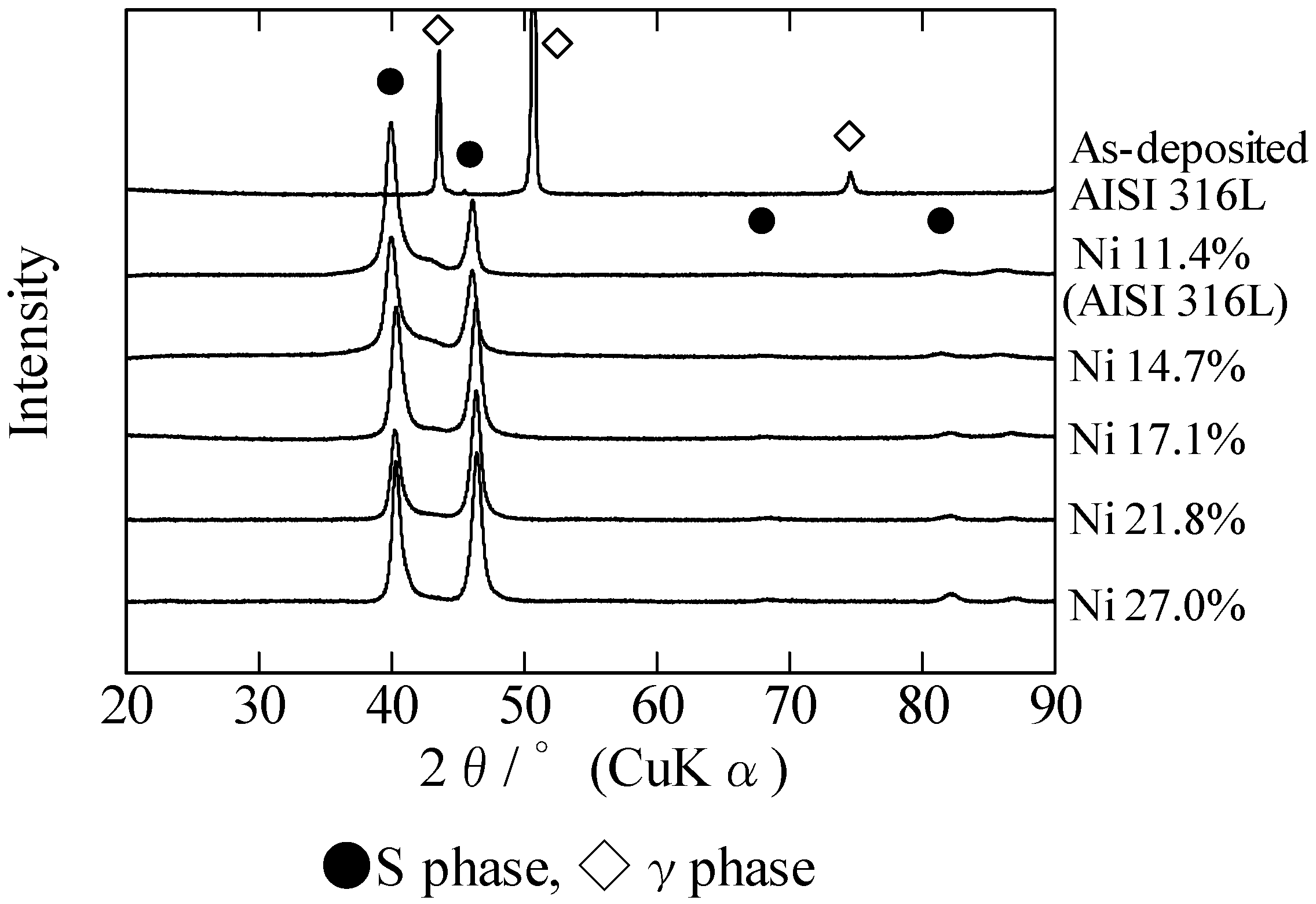

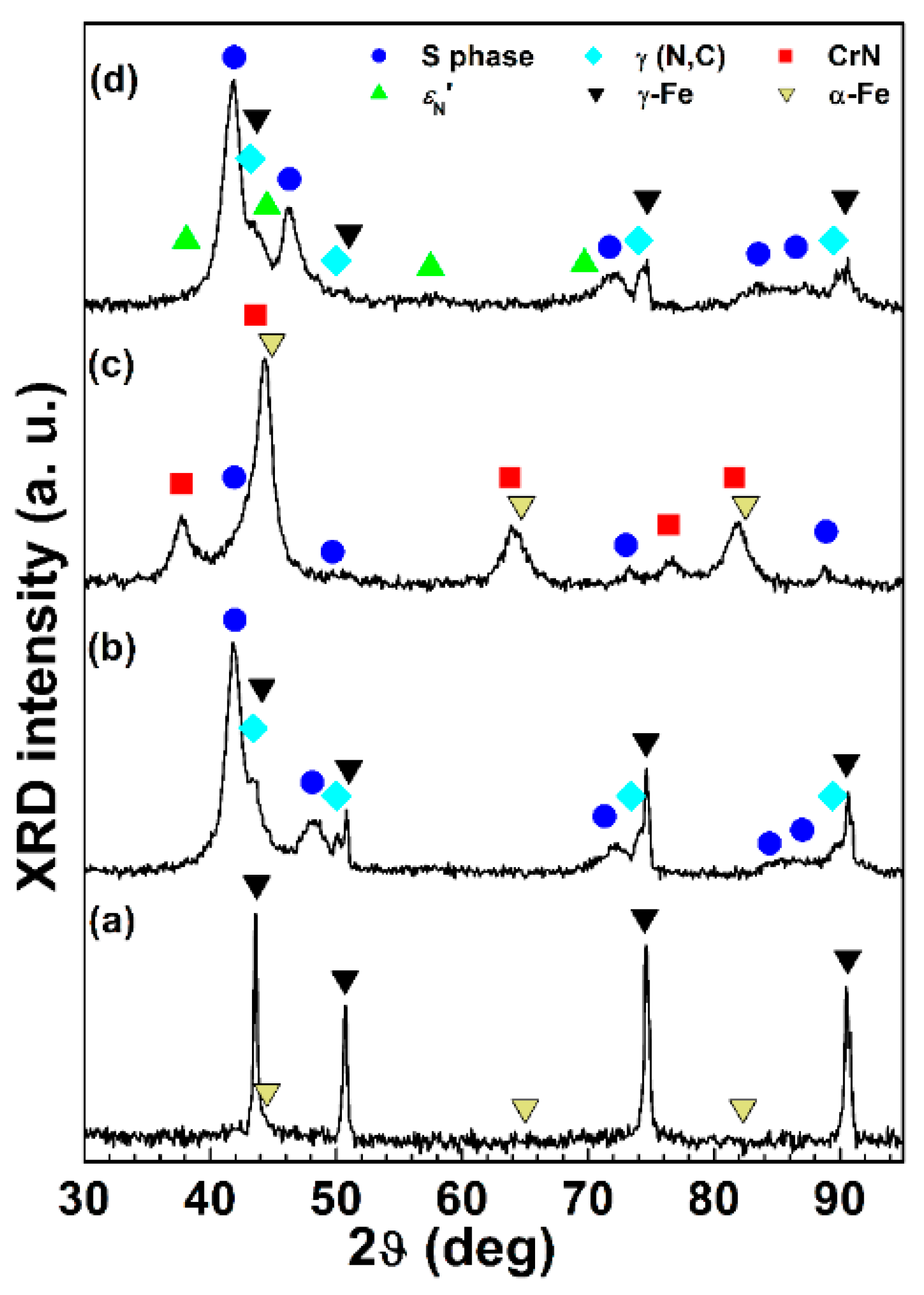

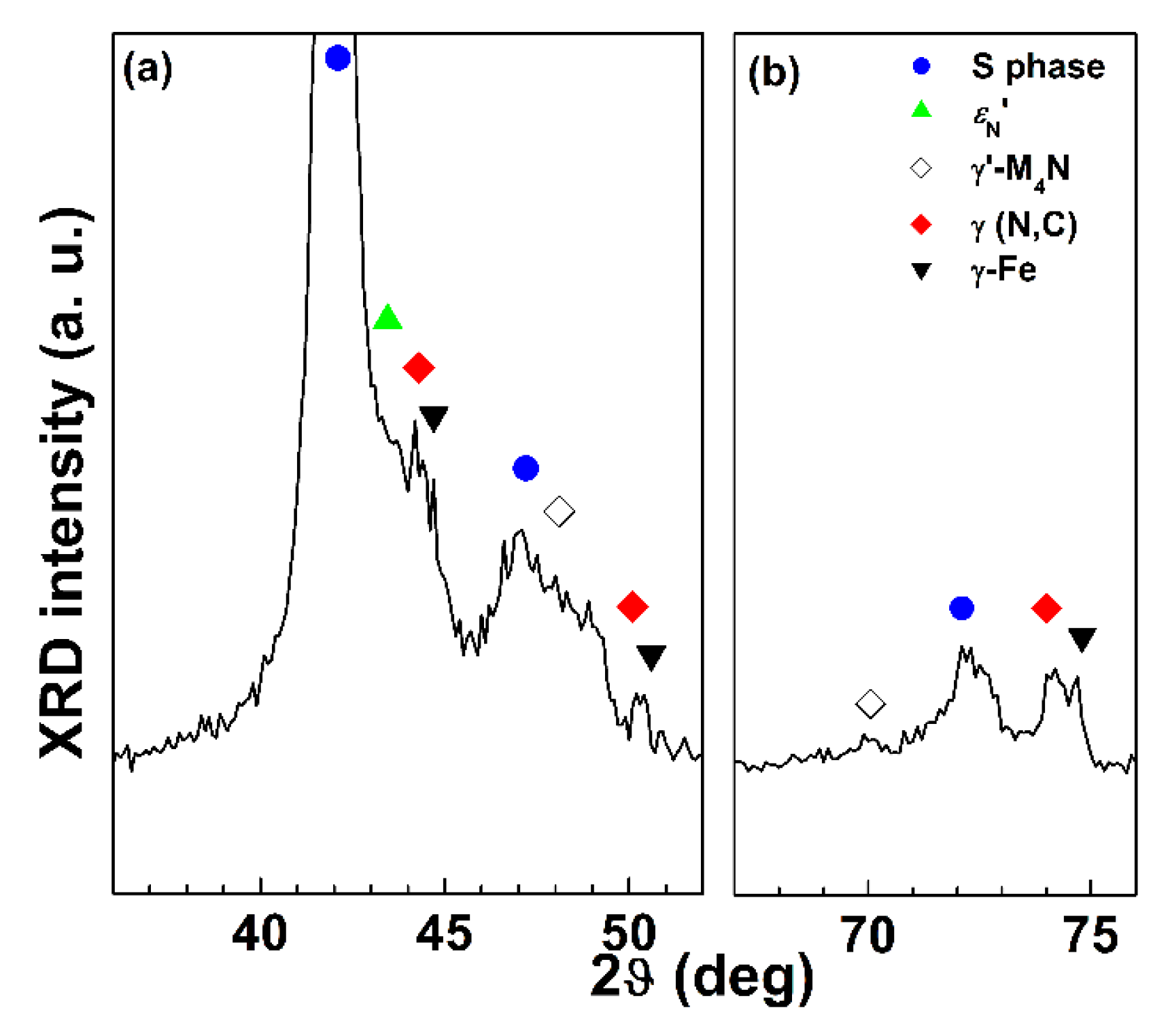

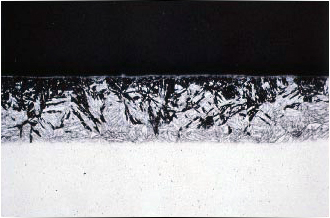

Plasma nitriding of stainless steels at low temperatures. Low temperature nitriding of austenitic stainless steels has been recognized to be a useful tool for increasing surface hardness wear and corrosion resistance 33 34. For instance at moderate temperatures like 420 c stainless steels can be nitrided without the formation of chromium nitride precipitates and hence maintaining their corrosion resistance properties. The nitrided layers produced by low temperature 400 500 c plasma nitriding on austenitic stainless steels aisi 316 304 and 321 have been characterised by x ray diffraction in conjunction. Unlike traditional nitriding treatments which are usually performed in the range 495 565 c and cause the formation of.

In the plasma nitriding processes nitrogen gas n 2 is usually the nitrogen carrying gas. In addition the laser powder bed fusion of aisi 316l stainless steel was treated by low temperature plasma nitriding at the temperature of 430 c. To avoid the drop in corrosion resistance of stainless steels in conventional nitriding precipitation of crn low temperature techniques like ion implantation plasma immersion ion implantation piii pi 3 and low temperature plasma nitriding were developed in this investigation four stainless steel grades ferritic. Surface and coatings technology 62 1993 pp.

In all cases a grade aisi 316 was applied which is considered representative for austenitic stainless steels. The influence of low temperature nitriding of stainless steel is in the following visualised and explained by a series of systematic nitriding experiments on austenitic stainless steel 12 13. The low temperature nitriding for these coatings produced the s phase thereby enhancing the wear resistance similar to bulk austenitic stainless steels. Other gasses like hydrogen or argon are also used.

At low temperatures no chrome precipitate forms on the component surface. Plasma nitriding of fe 18cr 9ni in the range of 723 823 k. Low temperature plasma nitriding is a recent development in the nitriding of stainless steels and iron superalloys. Oxidation of metals 36 1991 pp 143 156.

Low temperature plasma diffusion treatment of stainless steels for improved wear resistance.