Polyethylene Water Pipe Problems

Early 1960 s research of hdpe pipes established three major failure modes for pe pipe.

Polyethylene water pipe problems. Improved fittings solved that problem and the popularity of pex surged. Complaints about early pex water systems cropped up when the fittings used to connect the pipes failed and leaked. An expert can assess the current plumbing replace the pipes and expertly patch up any holes. Black polyethylene or pe pipe comes in very long rolls and is used in many areas for the water main between the meter and the house and for sprinkler systems.

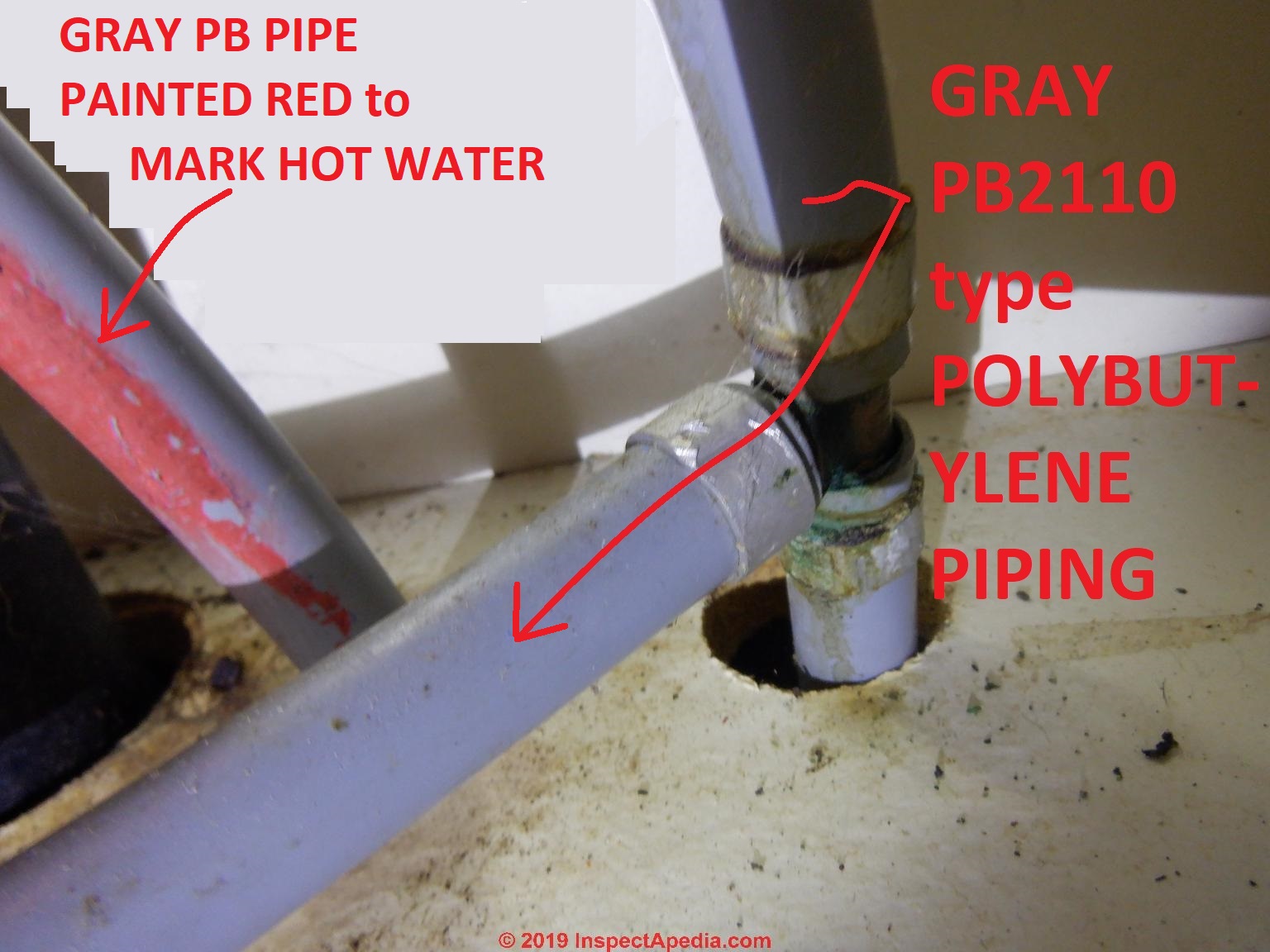

One of the problems with poly b is that the pipe may look fine from the outside but it s slowly deteriorating from the inside and could rupture at any moment. Polyethylene pipe is flexible and durable. Originally the problem with poly b seemed to be the fittings. Just like any other type of pipe poly pipe does not last forever and can develop leaks with time and with the help of tree roots.

Those living in older homes should have their water tested to see if lead is a problem. Polybutylene is a form of plastic resin that was used extensively in the manufacture of water supply piping from 1978 until 1995. It is easy to install on uneven terrain and it withstands the weather. There s just no way to tell.

Plastic pipe such as pvc polyvinyl chloride used for cold water only and cpvc chlorinated polyvinyl chloride used for both hot and cold water have been around for years and both are approved for use with drinking water. Unfortunately if there are polybutylene pipes within the home or leading into the home the best course of action is to replace the pipes entirely by hiring a re pipe specialist. Due to the low cost of the material and ease of installation polybutylene piping systems were viewed as the pipe of the future and were used as a substitute for traditional copper piping. It is ideal for a variety of water service and irrigation applications.

Often failure of the plumbing pipe takes place in the plastic fittings. Ductile failure mode i brittle failure mode ii and brittle chemical failure mode iii. More product details close. It is widely recognised that the long term durability of pe pressure pipe is dependent upon its resistance to inhibit the initiation and slow growth of cracks.

Ductile failure was associated with yielding and reflected a material s propensity to undergo large scale irreversible plastic deformation when under stress the yield stress describing the load intensity at which such effects occur.