Pressure Relief Device Inspection Frequency

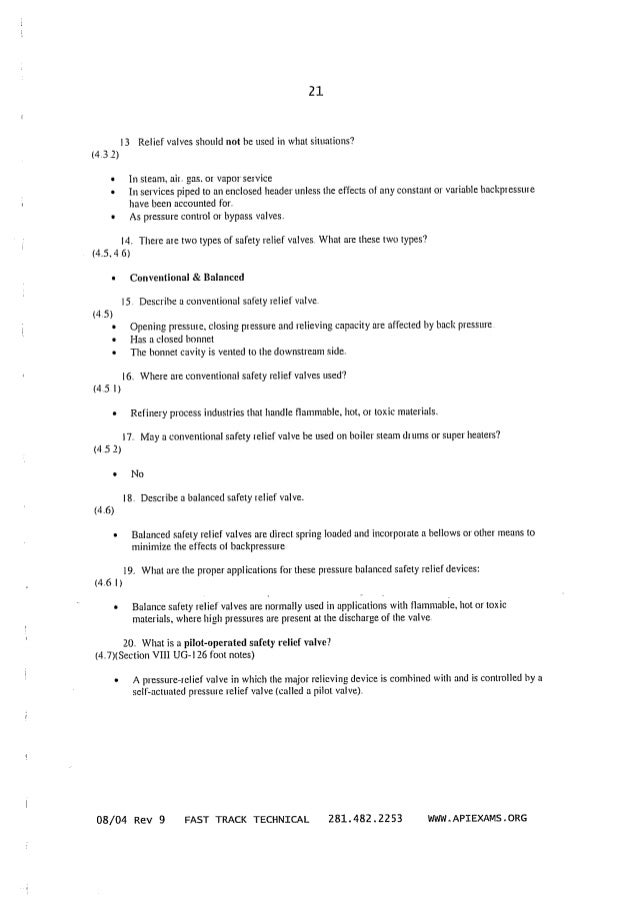

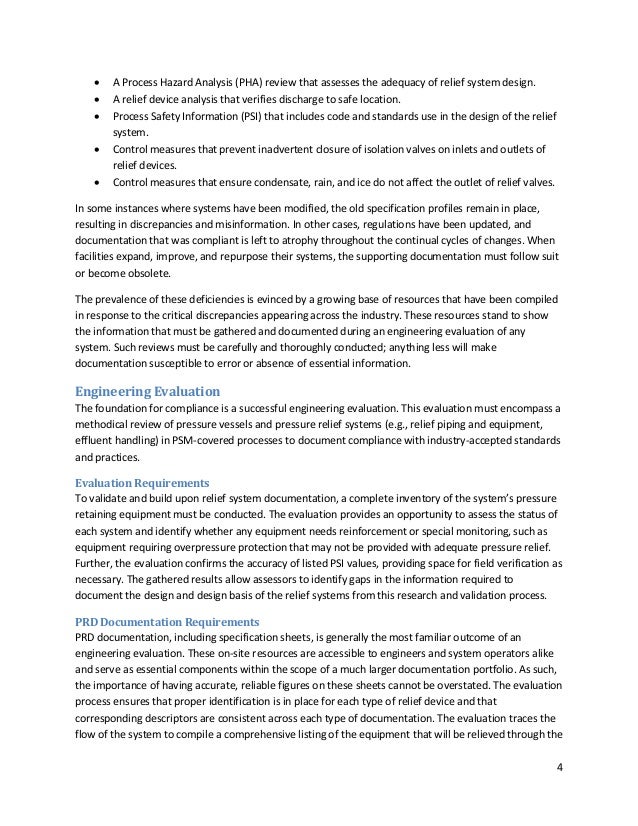

Api rp 576 inspection of pressure relieving devices is a recommended practice developed and published by the american petroleum institute api that describes inspection and repair practices for automatic pressure relieving devices commonly used in the oil and petrochemical industries and is intended when used properly to help ensure these devices perform properly.

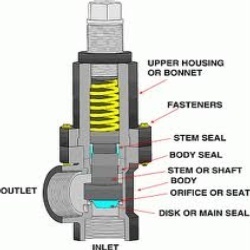

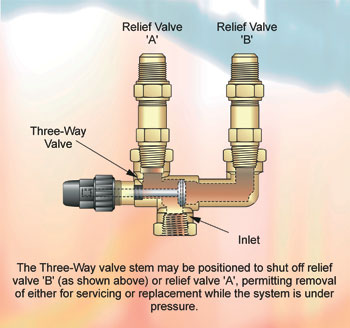

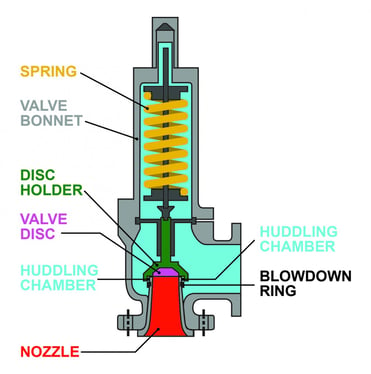

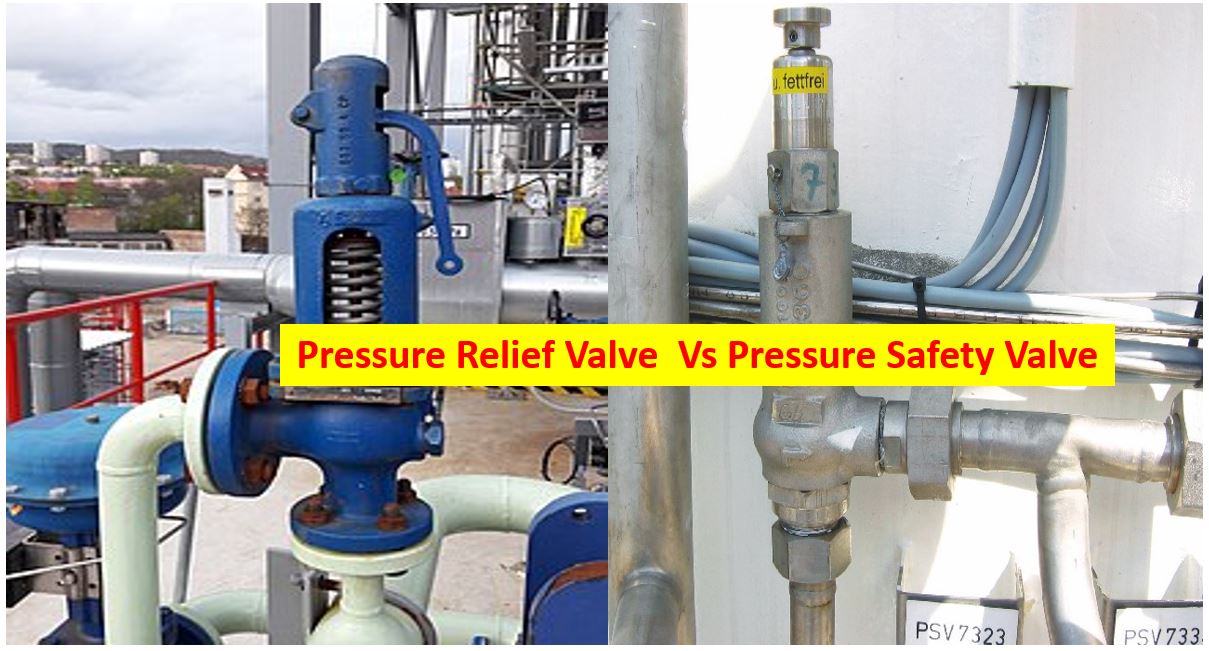

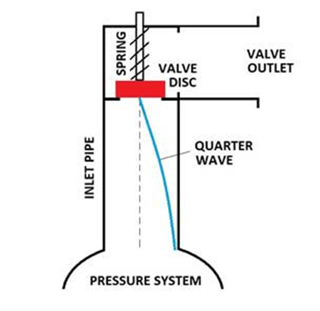

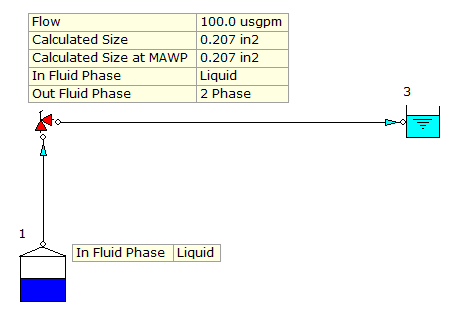

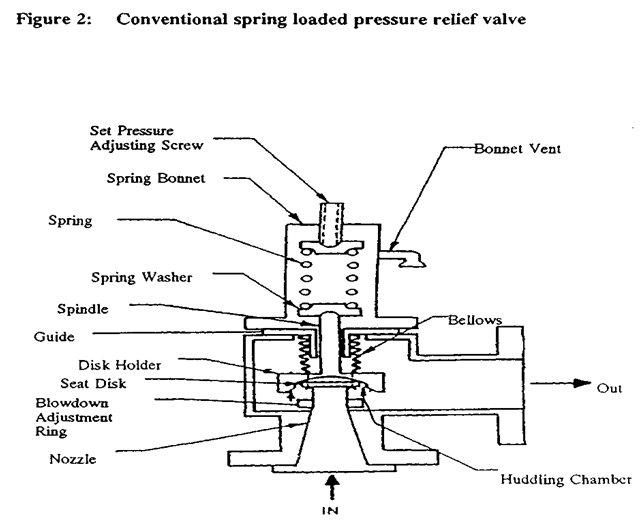

Pressure relief device inspection frequency. In general there is the at least every 5 years interval that is ever so popular and the vast majority of manufacturers will require their rv s the be. The inspection should verify that. Their proper function is essential. Repair and alteration by api recommended practice 576 inspection of pressure relieving devices by.

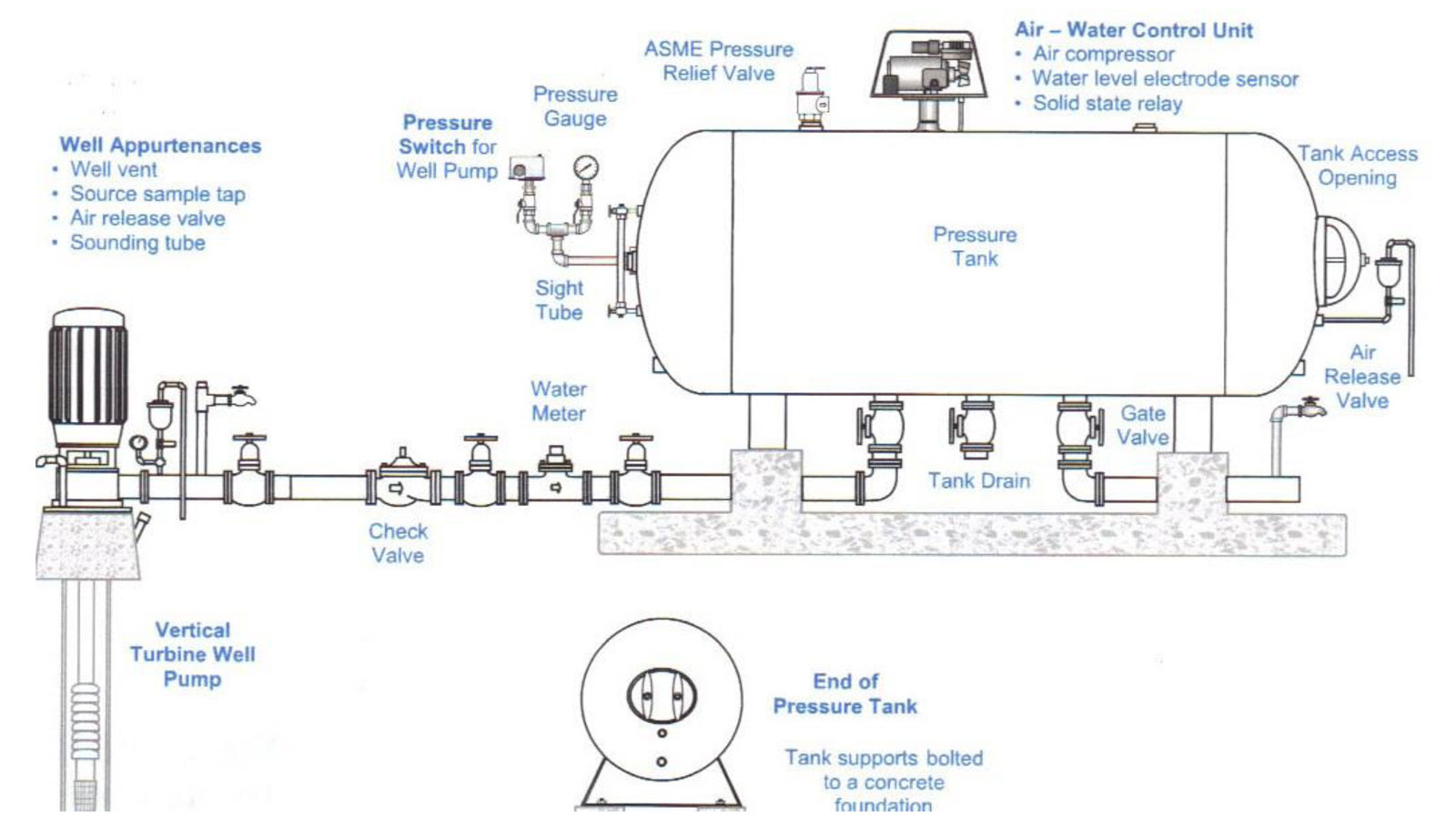

Pressure relief device inspection review of nbic part 2 par. Asme ptc 25 for pressure relief devices which majorly is used for assessment of testing facility and apparatus for safety valves. 2 2 5 pressure relief devices pressure relief devices such as safety valves pressure relief valves and rupture disks prevent a system from becoming over pressurized. In my last several process safety courses i had several request for code requirements surrounding relief valve maintenance e g.

Determining the correct interval for pressure relief valve inspection testing and maintenance remains a major challenge for facilities covered by the u s. Inspection replacement and or rebuild frequencies. Occupational safety and health administration process safety management standard. A pressure relief device is the last line of defense for safety.

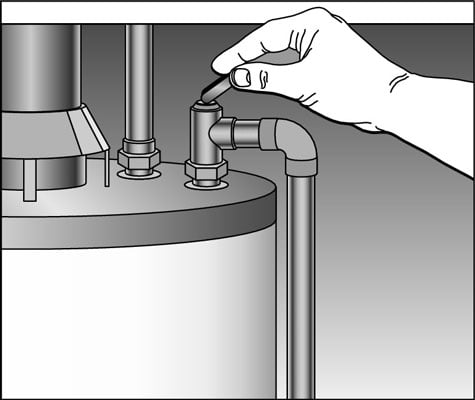

Pressure relief devices are used to provide a means of venting excess pressure which could rupture a boiler or pressure vessel. The maximum thorough inspection intervals and pressure relief valve servicing intervals that can be assigned for specific types of pressure equipment are defined in a progressive grading system that was developed based on industry experience. Updated november 2016 1. Pressure relief devices must be inspected according to the frequency listed in table 3.

If all other safety devices or operating controls fail the pressure relief device must be capable of venting excess pressure. Following link provide you the step by step activities required for pressure safety valve inspection in manufacturing process.