Rack And Pinion Gear Ratio Calculator

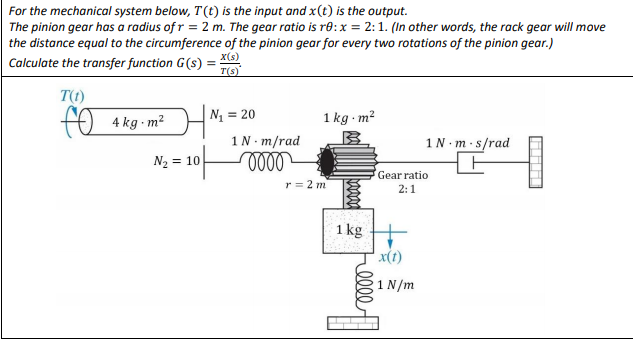

An important principle is that you realize that the calculation and selection rack pinion gearbox and motor is done by trial and error.

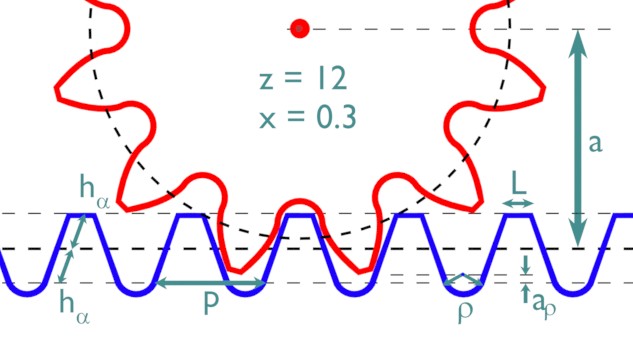

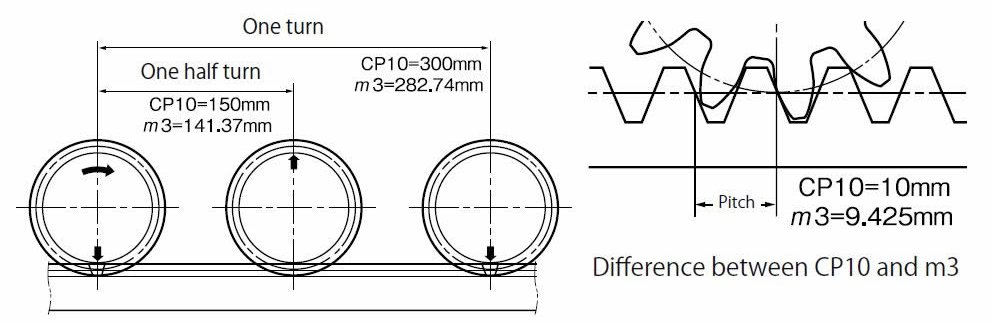

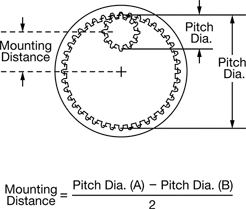

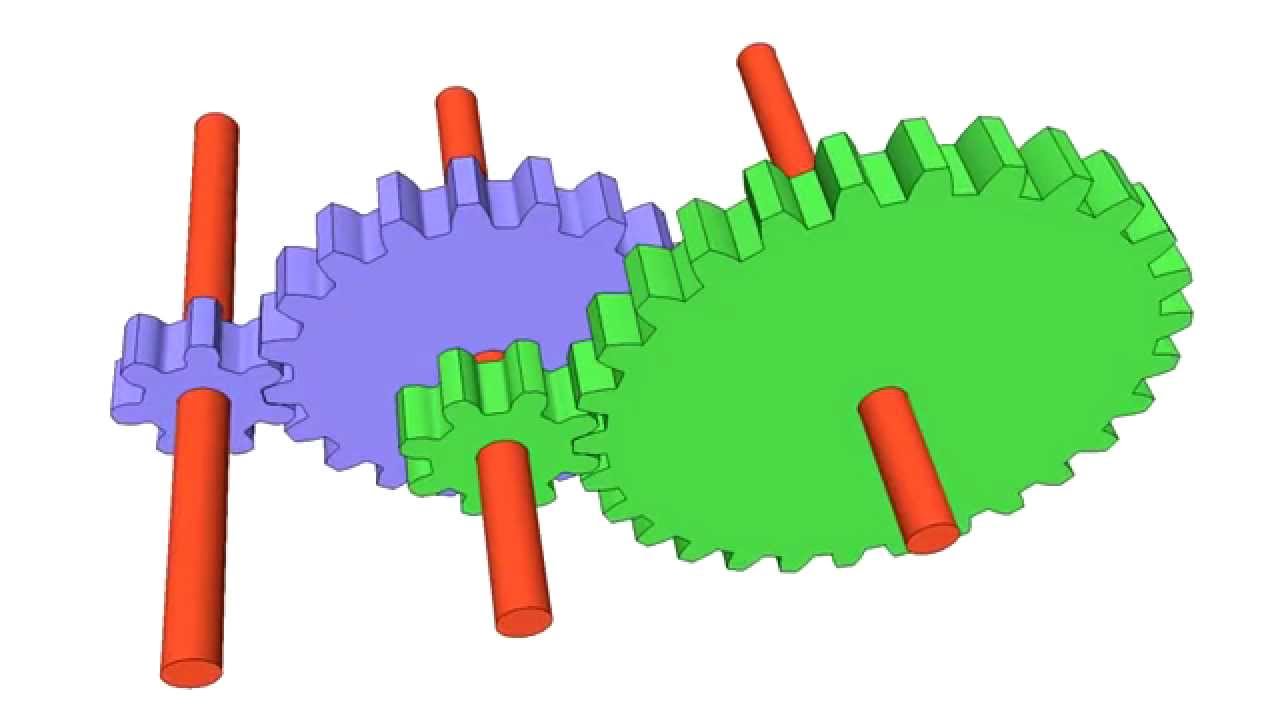

Rack and pinion gear ratio calculator. The following online calculator computes the basic dimensions and tooth profiles of a meshing rack and pinion based on the pinion s module number of teeth pressure angle usually 20 and profile shift. Sizing you should size your pinion and its teeth to suit the recommended materials for gear wheel manufacture e g. Enter the precision grades of the two gears as well as absence or existence of tooth form correction s. The rack s teeth are trapezoidal while the pinion has an involute tooth profile.

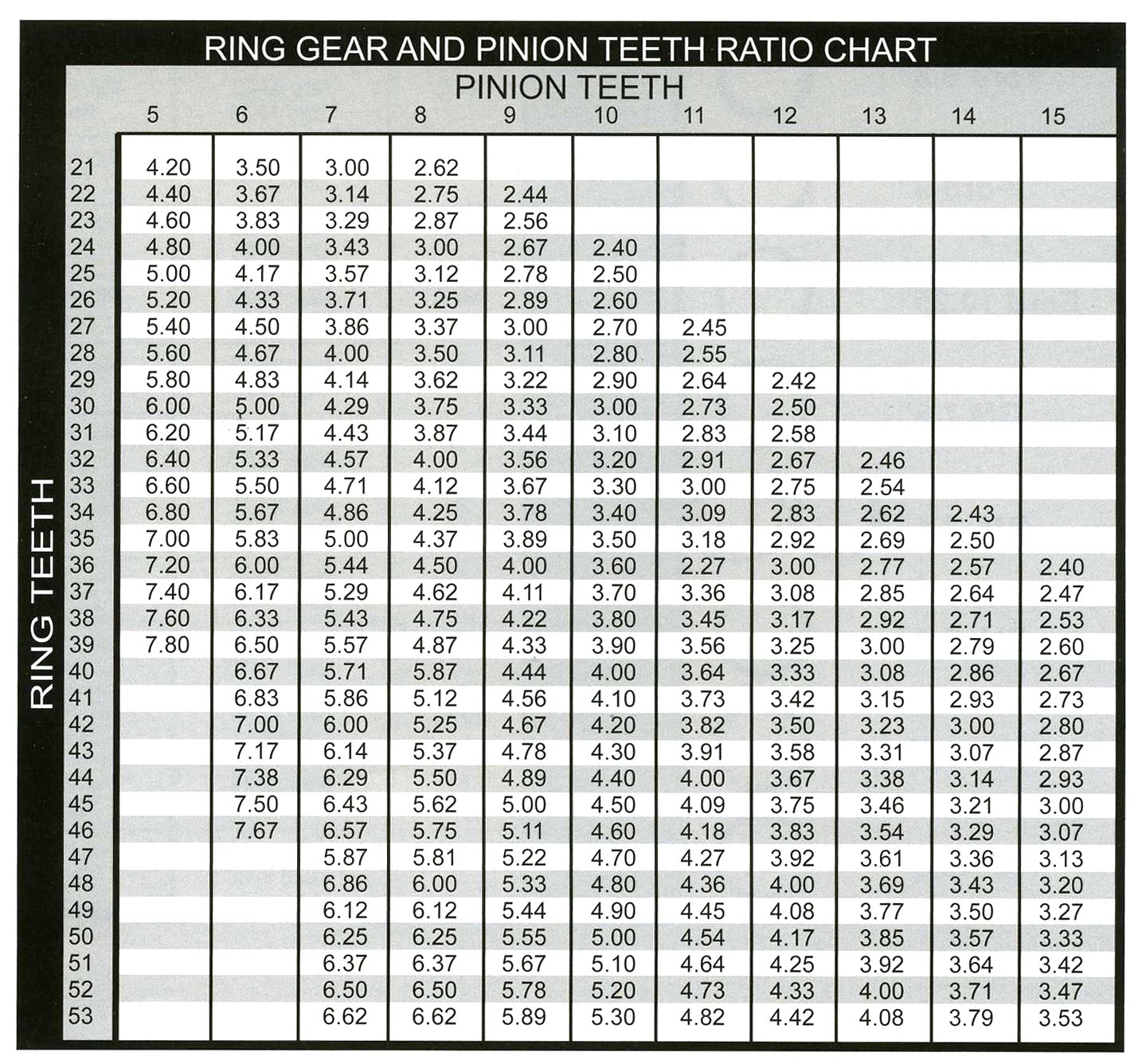

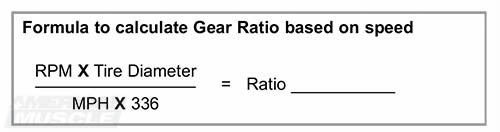

Choose from our selection of rack and pinion gears including metal gears and gear racks plastic gears and gear racks and more. Diameter of the gea. Results 1 to 5 of 5 thread. For example a 3 73 gear ratio requires 3 73 driveshaft rotations to turn your tires once around.

A 1 1 tuning is also possible by using sprockets. Rack pinion gear calculation. 07 14 2011 12 15 am 1. The entire spectrum of a pinion transmission can be shifted to fast or slow with the secondary ratio to the rear wheel.

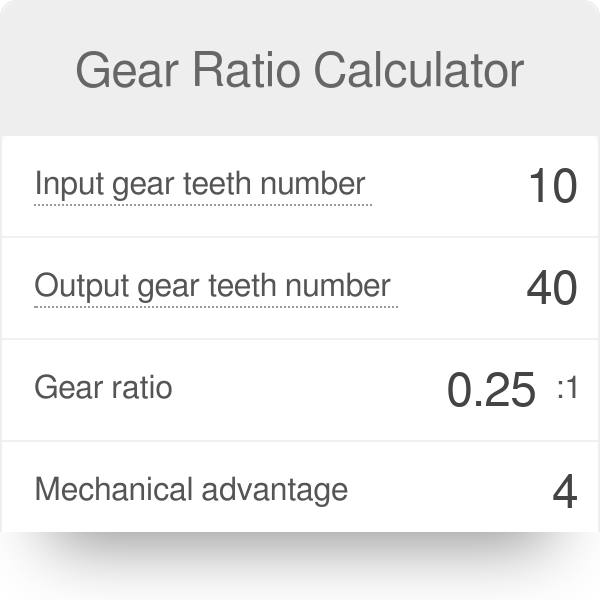

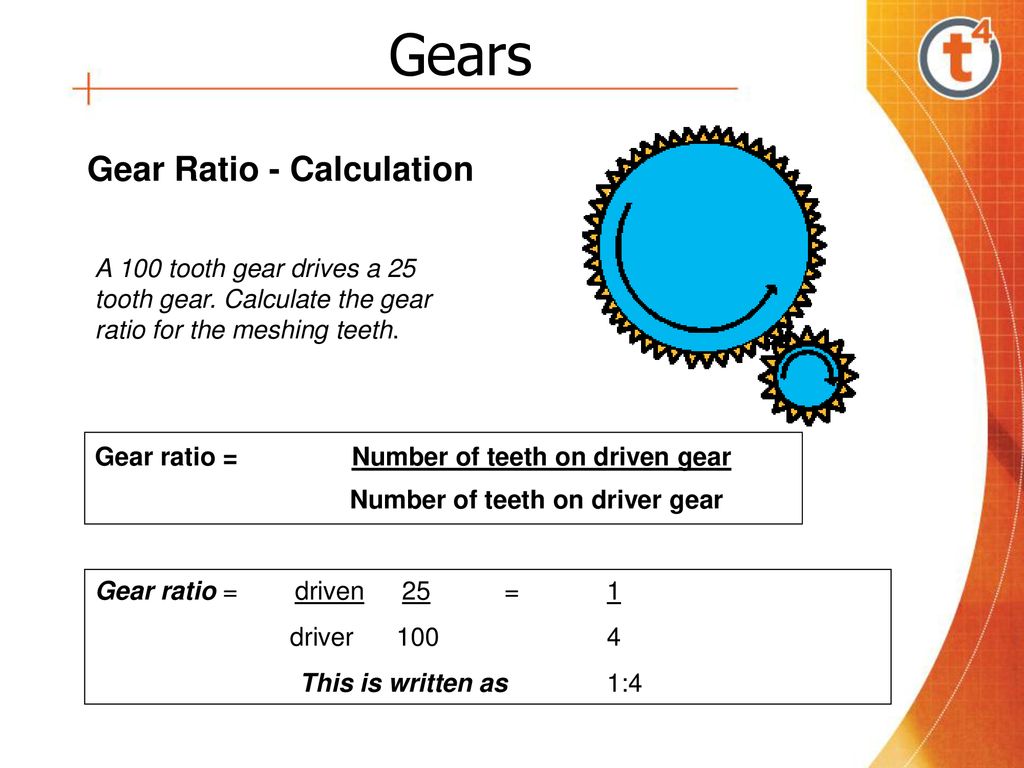

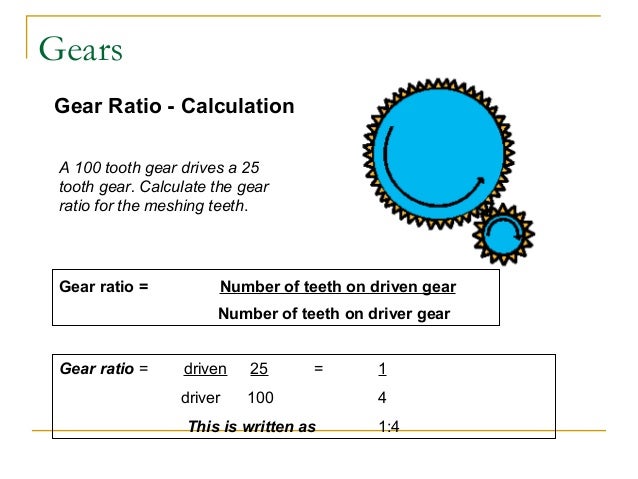

You should be able to find your gear ratio listed on the axle tag however if that has gone missing you can simply count the number of teeth on each gear and divide the number of ring gear teeth by the number of pinion gear teeth. The pinion gearbox calculator helps you to choose the ideal gearbox tuning. The internal gear ratio for each gear of all types of gearboxes is already defined in our calculator. Rack pinion gear calculation.

View profile view forum posts titanium join date aug 2004 location ohio usa posts 2 128 post thanks like likes given. If needed also input the gear cutting tool s tip rounding radius coefficient. The force the rack sees. You have a good chance that you have to do the calculations again with other parameters such as the diameter of the pinion or the quality read in this case.

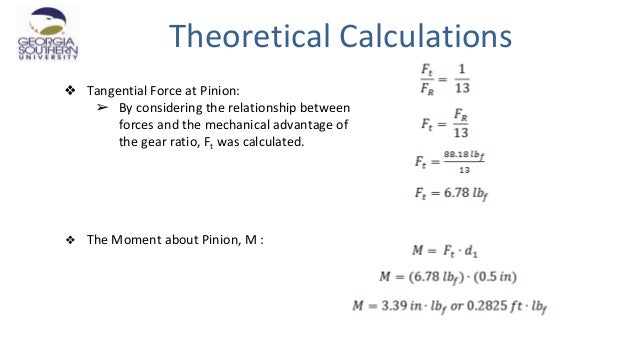

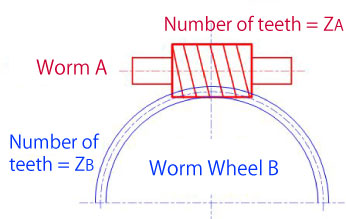

Input the number of teeth of the pinion and the gear. Carbon steel see material selection below. Unlike ball screw sizing which must take into account factors such as characteristic and critical speeds end bearing considerations and the effects of preload in addition to basic thrust force and drive torque calculations rack and pinion drive sizing is primarily based on three factors. Hardness of the rack.

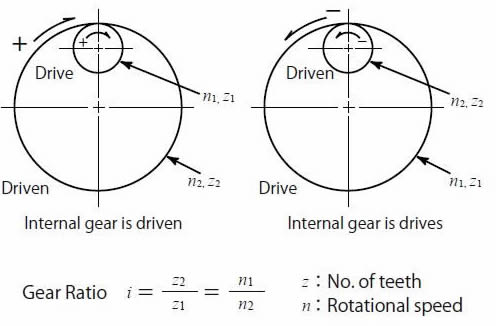

Input the center distance between the pinion and the gear. In order to obtain the gear ratio for a particular application you need to take the ratio of any one of the following. Rotational speeds of the pinion to the gear 2.