Reynolds Steel 520 Vs 853

The benefits of air hardening steels are particularly noticeable in the weld area of reynolds 853 where unlike conventional steel alloys strength can actually increase after cooling in air immediately after welding.

Reynolds steel 520 vs 853. Reynolds 520 chrome moly cold worked steel. 853 is the highest grade normal steel reynolds makes. The 853 will be very slightly lighter. The reynolds tube company was founded in 1898 by john reynolds in birmingham england but traces its origins back to 1841 when john reynolds set up a company manufacturing nails.

I previously rode an equilibrium in reynolds 520 which i bought second hand stripped and built up with ultegra group and mavic ksyrium elites. 853 is heat treated to give high strength and damage resistance and the steel properties allow thin walls to be used so that lower weight but fatigue resistant structures can. With similar properties to our original 531 brand alloy. An 853 bike using the same tube sizes and wall thicknesses as 520 bike will be almost identical in weight and stiffness.

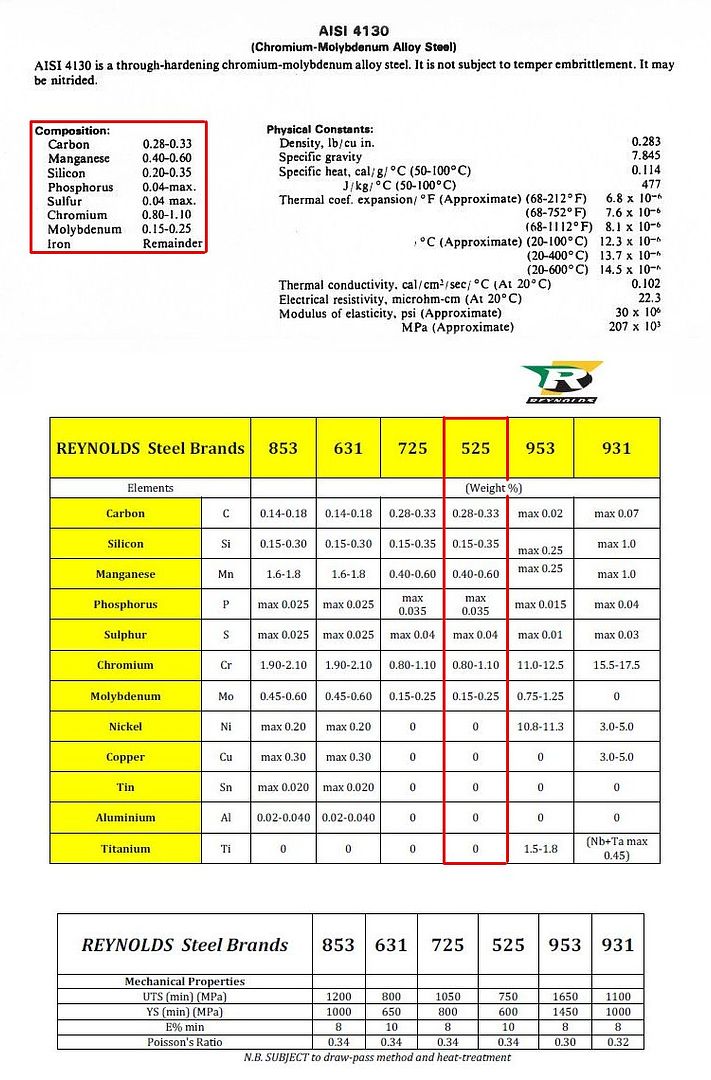

Reynolds broken down reynolds 953 maraging stainless steel reynolds 853 heat treated air hardening steel reynolds 725. See reynolds and on one under the materials bit 853 does seem fairly impervious to rust though bare patches on mine. All steels have essentially the same stiffness so differences in ride feel will come down to the dimensions of the tubes. In 1897 the company patented the process for making butted tubes which are thicker at the ends than in the middle this allowed frame builders to create frames that were both strong and lightweight.

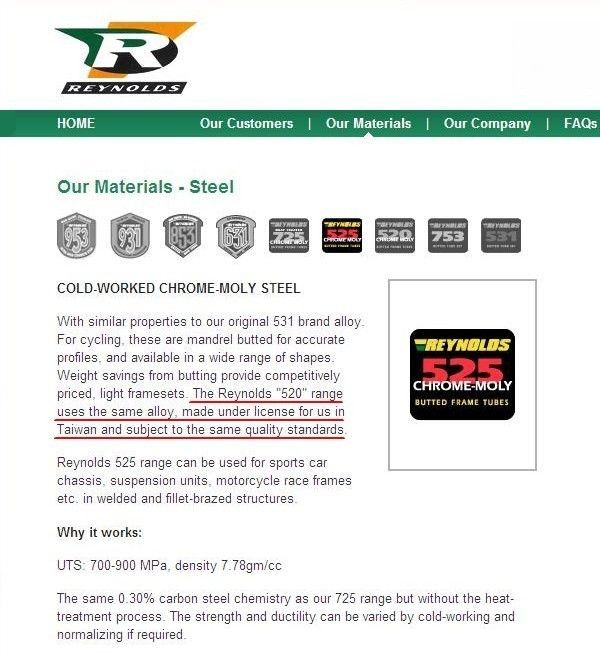

520 makes a good riding frame but is will weigh more often a pound or more than an equivalent 853 frame. For cycling these are mandrel butted for accurate profiles and available in a wide range of shapes. If you look at a piece of cheap steel tubing you will see the join as a different coloured line running down the tube. For example the old reynolds 531 and all better tubes from reynolds are seamless as is their cr mo 520 and 525 identical except 520 is license built in the far east so not all 4130 cr mo is equal.

520 is just standard cro mo 4130 i think. There is also a thinner 853 pro team tubeset and also the stainless 953. 520 is a taiwan made cro moly steel that is not heat treated but made to reynolds standards same as their 525 tubing. A lot of the italian builders are going with carbon tails on steel bikes because it s easy and cheap to do.