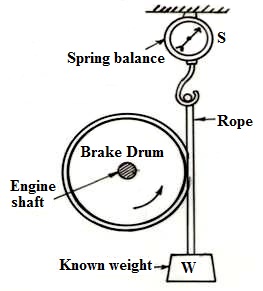

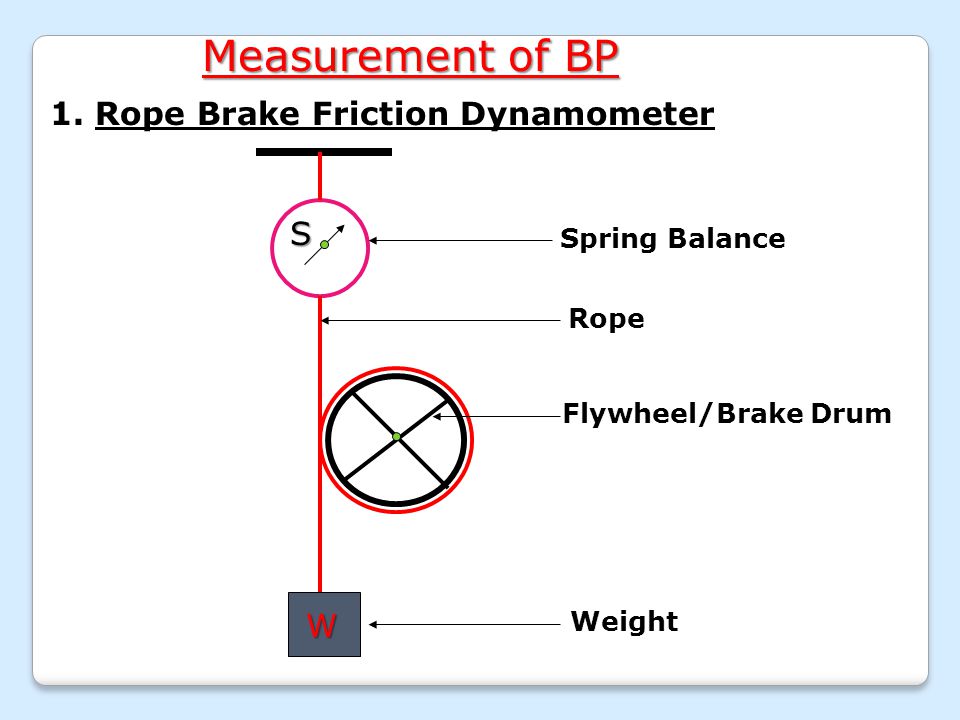

Rope Brake Friction Dynamometer

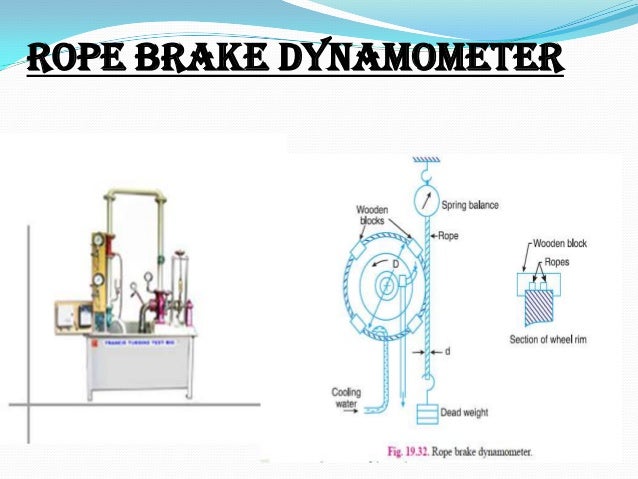

The rope brake dynamometer assembly is held between a plummer bearing block prime mover.

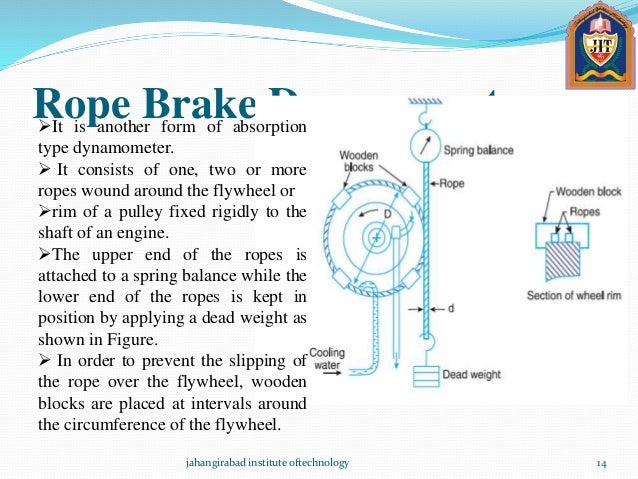

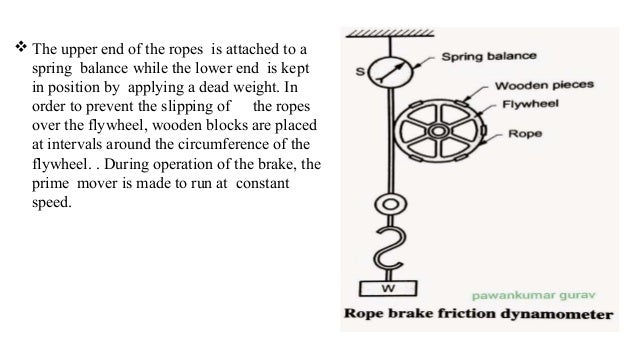

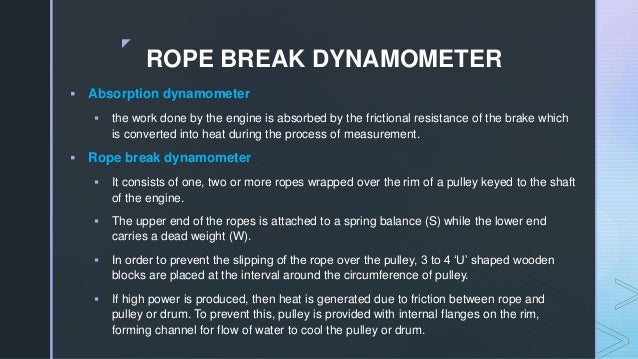

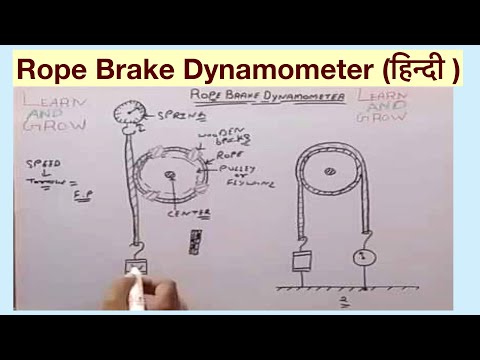

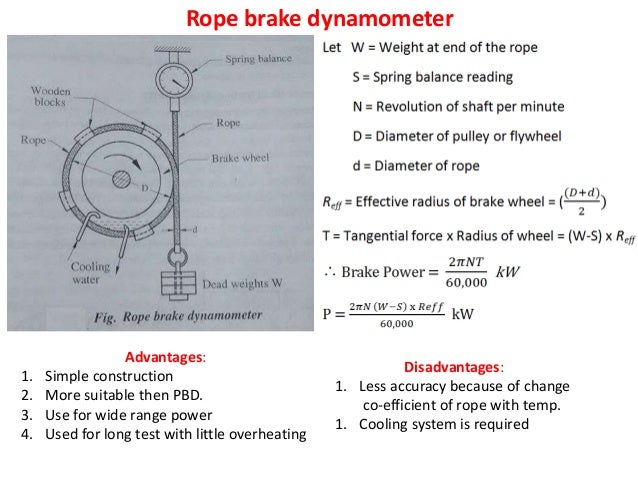

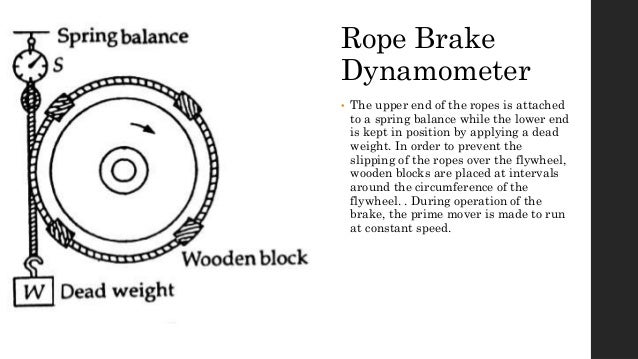

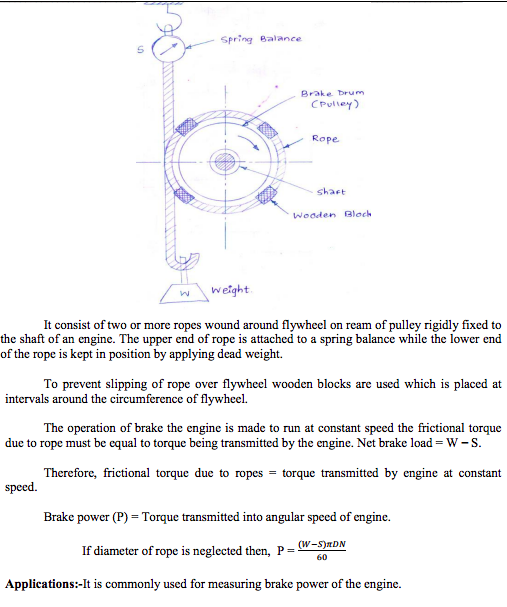

Rope brake friction dynamometer. Rope brake dynamometer department of mechanical engineering svpcet 2013 2014 15 chapter 6 conclusion 24. Rope brake dynamometer is used to measuring the power of the engine shaft. In this brake two or more ropes rest on the rim of a pulley. And it contains a shaft that will measure the power from rotating the shaft.

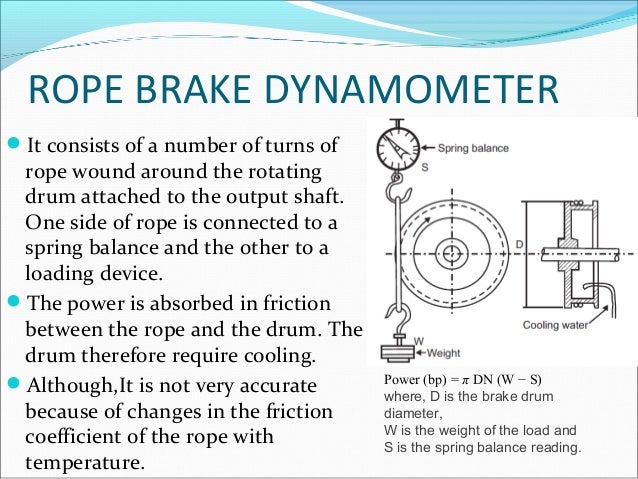

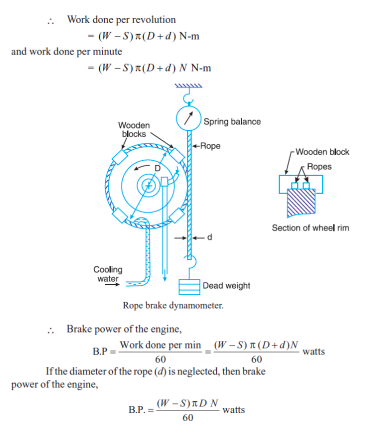

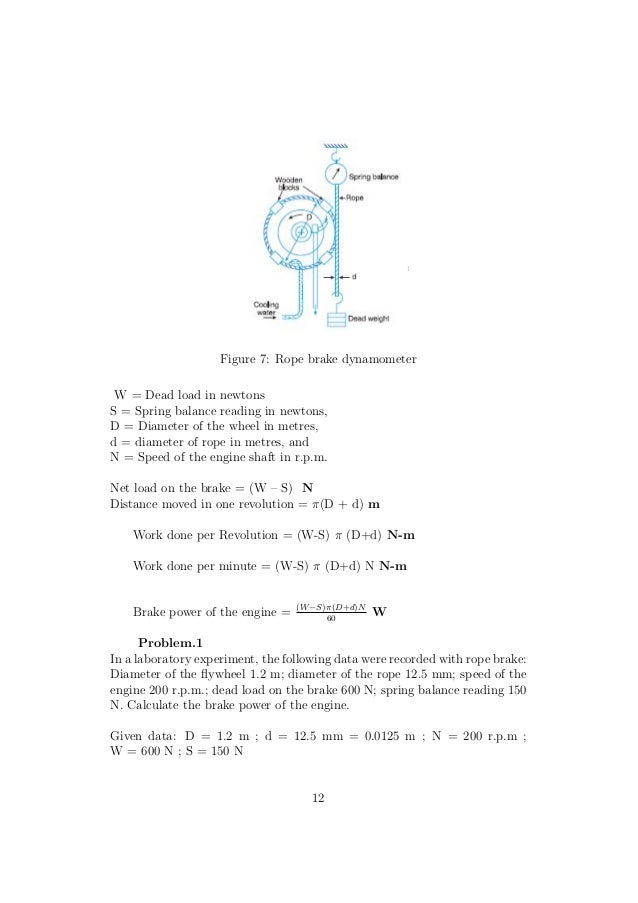

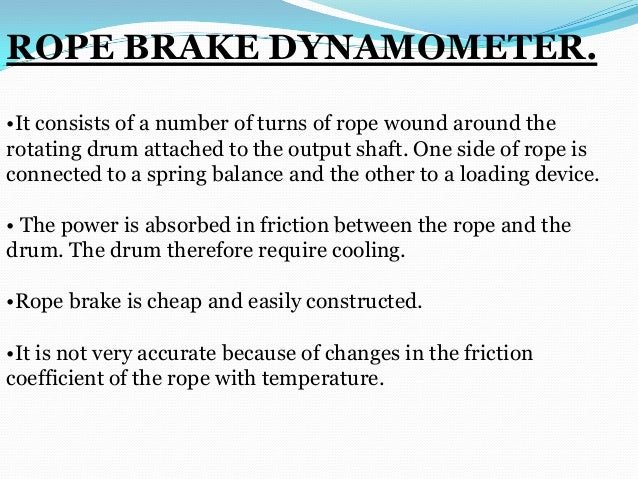

Rope brake is cheap and easily constructed but not a very accurate method because of changes in the friction coefficient of the rope with temperature. The most commonly used dynamometer for tests in the laboratoty is. The bp is given by bp p dn w s where d is the brake drum diameter w is the weight in newton and s is the spring scale reading. Figure 25 8 shows a rope brake dynamometer.

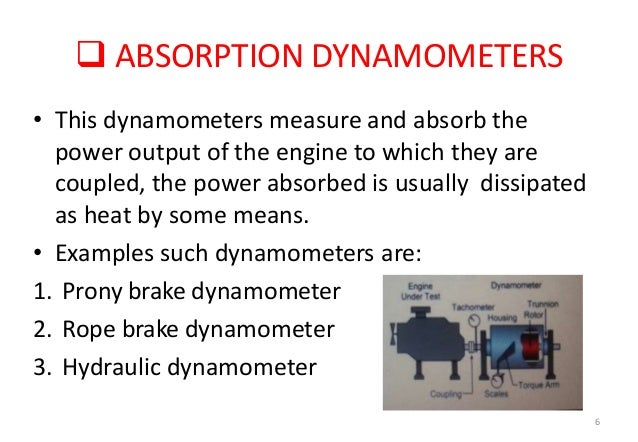

Dynamometers can be broadly classified into two major types 1 absorption dynamometers in this type work done is converted into the heat by friction while being measured. Rope brake dynamometers are cheap and can be constructed easily but brake power can t be measured accurately because of change in the friction coefficient of the rope with change in temperature. Therefore drum in rope brake requires cooling. Also it has ropes which are one rope connecting to a spring balance and the other rope attached with the weight.

So this kind of dynamometer it basically works on. Thus the net force on the scales produced by the frictional moment is p tare. Prony brake dynamometer rope brake dynamometer. The brake power is given by the formula brake power bp π dn w s where d is the brake drum.

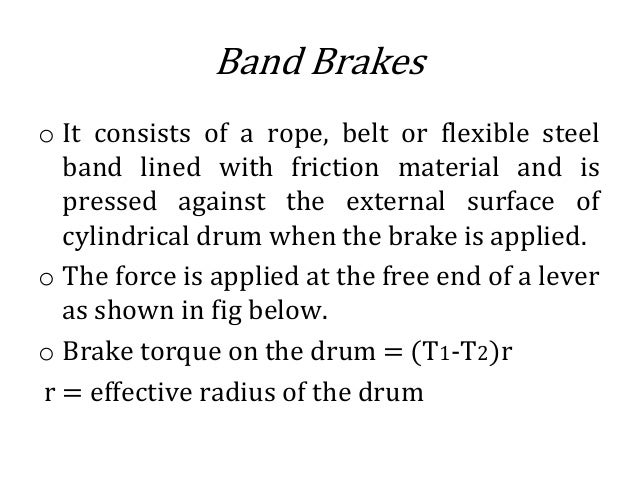

2 transmission dynamometers in this type the work is not absorbed in process but it is utilized after the. To find the tare support the brake on the edge at b and weigh the tare on the scales. Good quality brake lining is fitted on a half round plate.