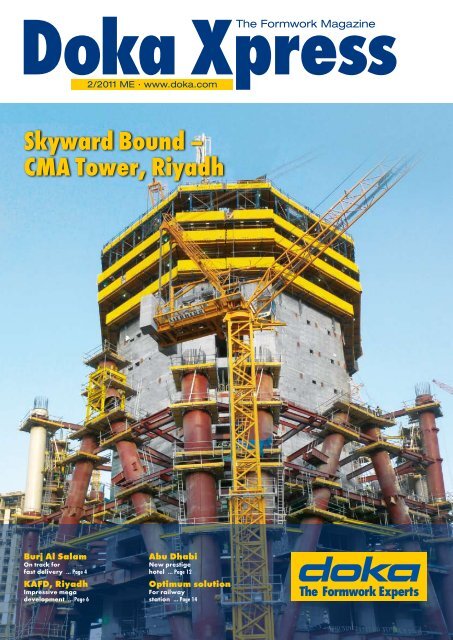

Retaining Wall Doka Formwork

Doka offers a wide range of proven wall formwork for all jobsite situations all fields of use and all specifications regarding the concrete finish.

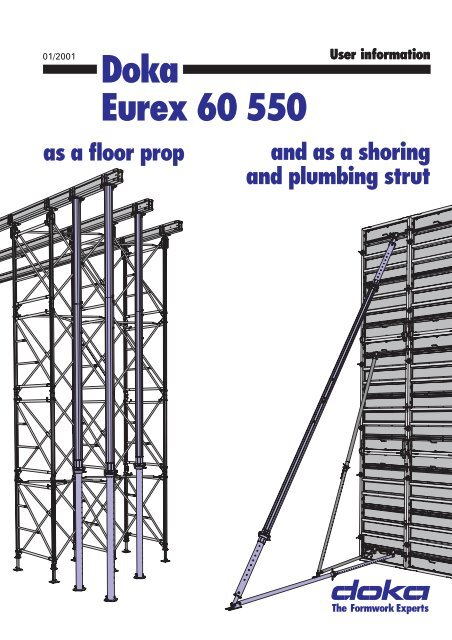

Retaining wall doka formwork. The plywoods form facing 3 is your choice and can be selected for specific jobsite requirements. Achieve faster pour rates quicker assembly while spanning large distances without intermediate support. Concrete wall formwork single side formwork single bracket retaining wall formwork 1. The strong and durable self spanning steel formwork the all steel modular form system is a waler less large size panel system that is best suited for columns piers pier caps beams retaining walls foundation walls and culverts.

The single sided bracket is compatible with horizon s wall formwork. Aluminum retaining wall system. Other usage are in casting underground chambers water tanks etc. Formwork built by doka s pre assembly.

When one sided concreting is done pressure of concrete is transmitted to the base through the retaining frame. Pouring do not exceed the permitted fresh concrete pres sures. Peculiarities of retaining wall formwork one sided formwork is used for building retaining walls columns and foundations. The doka formwork beams h20 1 and the steel walings 2 are spaced closer together or further apart depending upon what pour pressure you desire.

Once assembled each. Doka offers a wide range of proven wall formwork systems for all jobsite situations all fields of use and all specifications regarding the concrete finish. Its design features consist in availability of a modular frame system buttress. Erecting the formwork doka products and systems must be set up so that all loads acting upon them are safely transferred.

Over high pouring rates overload the form work cause greater deflection and risk breakage. The maximum wall height is up to 8 m. The concrete pressure are reliably transferred to the embedded anchor systems.